First we see the knives laid out along with all of the materials required. The wood has been cut down to size, squared up, and the scales (for the santoku) have been cut as well as have their G10 liners glued up.

(The wood isn't really called "baconwood" - the owner dubbed it this name as it reminds her of bacon)

The blades are wrapped in protective tape and then the scales were removed from the handles. Sorry no pictures, I should have taken some but I forgot. The procedure is to grind the heads of the rivets off and then punch them out - scales fall off.

The holes in the tangs were drilled out to a larger size to accommodate the pins I use. In case you're wondering why I need to drill the holes out, the Japanese use rivets with large heads yet tiny shafts so the factory pin holes are very small. The tangs are hardened and require a carbide drill bit to cut through them.

Here you'll see the knives laid out at the point ready to have the wood attached. I have some more fitting to still do to ensure a clean fit up but otherwise the next step will be mounting the wood.

You'll notice that the gyuto's tang has been ground down to make the hidden tang conversion. The owner requested a hidden tang handle on this knife because she wants to show the maximum amount of "baconwood"as possible.

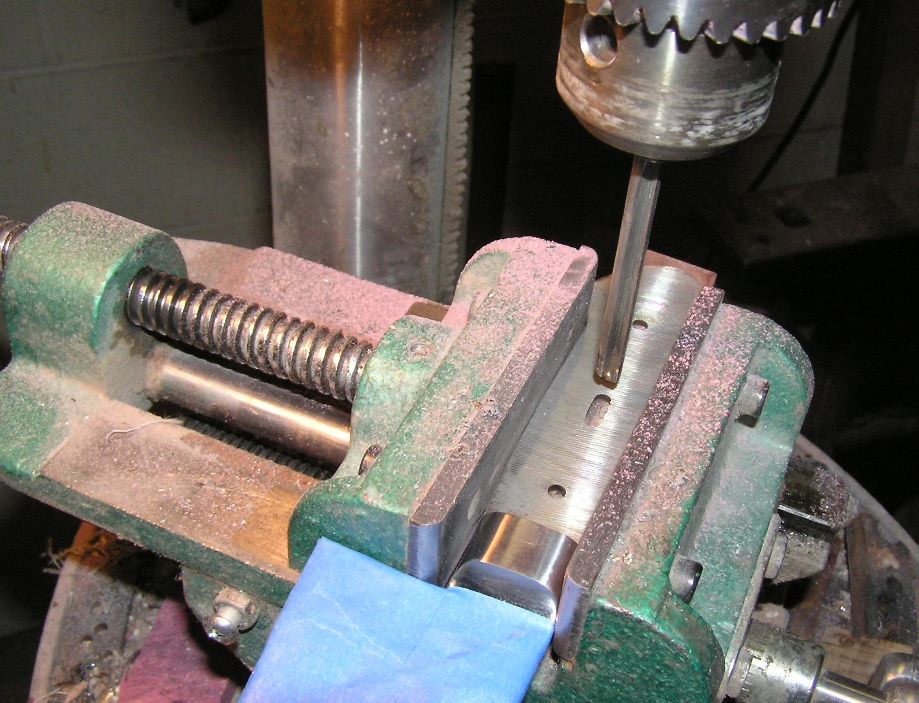

Here I'm drilling the pin holes for the santoku. I bring the whole assembly (knife included) to the drill press to drill my pin holes. I've found over time that if I do it this way I can make one pass through both scales and get perfect alignment without having to run the risk of over-sizing the holes from drilling the second scale as is more commonly done. *Note - Doing the drilling like this works great for tapered tangs - perfect fit every time.

I finish the holes by using a reamer (shown in the picture) to get the perfect size for a (hopefully) perfect fit.

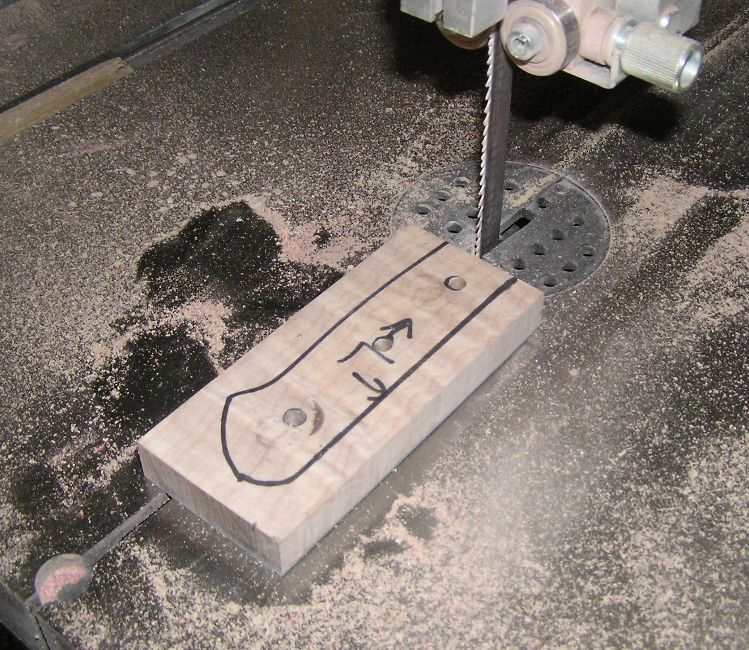

I then cut out the shape (pattern) for the scales.

Here are the santoku scales with pins inserted part way, ready for glue up.

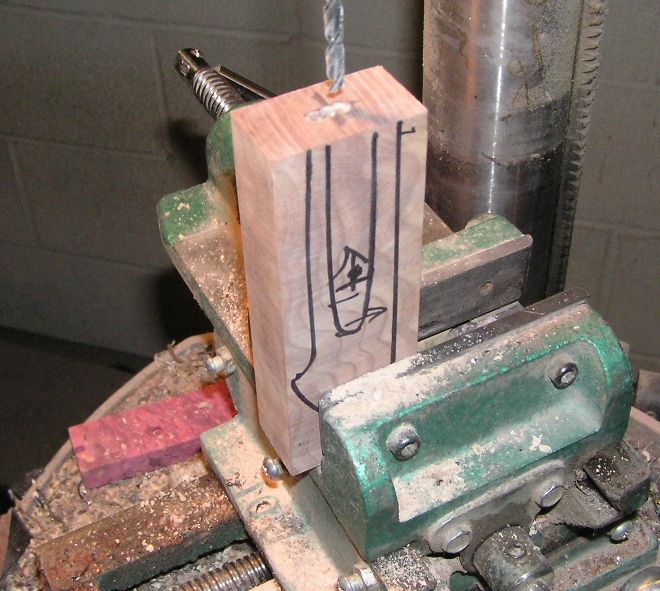

I then moved onto drilling out the tang hole in the "baconwood" block.

Then onto the fun part - burning in the tang!

The process starts out by heating the tang's tip to orange color (very hot).

Then I push it on home, sometimes we get flames.

Also lots of smoke too. Good thing I have a dust collector set up below sucking the smoke out of the shop.

Then finally I drilled the single pin hole that this handle will have.

Now for mounting & gluing.....

The wood is mounted and epoxied - cures overnight.

Here are the knives after glue up, clamps removed.

Here I cut the gyuto handle profile from the baconwood block.

The wood is ready for shaping.

Rough shaping the wood into the form of a handle. This is the pucker part.

Both handles are rough shaped using a 36x grit belt followed by an 80x belt which you see in the pictures above. I grind the bolsters at the same time to get a flush fit.

I then go through a series of belts up to 220x.

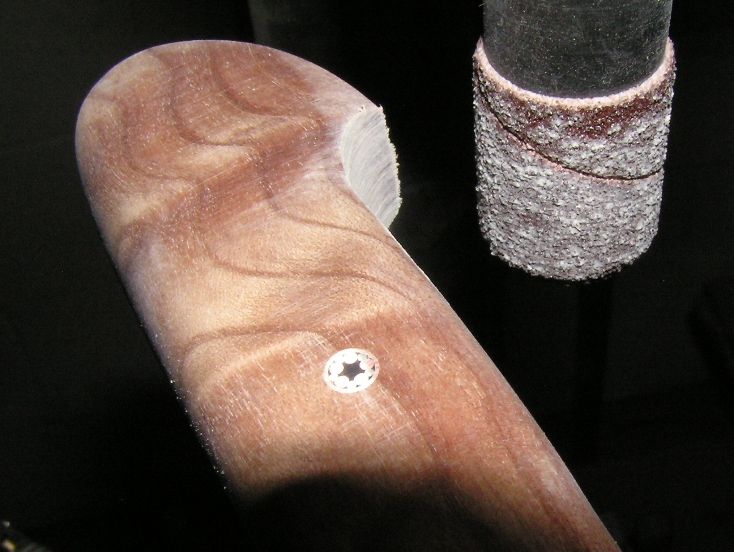

Now to shape the curl (sometimes referred to as the bird's beak) section of the handle. Since I don't have a nice small wheel attachment for my belt grinder I have to use little drum sander spindles in the drill press.

Here's what I'm looking to achieve.

I then use sandpaper strips to (shoeshine) shape the curl (bird's beak) into a comfortable grip. This step is important since the wrap around fingers land here.

Here's what I'm after.

Now back to the grinder for some refinement, I take each handle up through to 400x. The handles are now ready for hand sanding & oiling.

The handles have been wet sanded with both fine sandpapers and then with very fine steel wool.

I then seal the wood through oiling. I will start this process continuing on for at least two days, until I get just the right level of finish I'm looking for.

Here they are finished up...

To have a custom handle made for your Japanese kitchen knife please contact us a JapaneseKnifeSharpening.com